High-Performance Steel Grating Solution: Withstands Coastal Salt Spray, Prevents Worker Slips, and Reduces Fouling

- Overview

- Recommended Products

-

Full Material Coverage

Our steel grating is manufactured with premium low-carbon steel or stainless steel, through advanced welding/riveting technology. It features high strength, corrosion resistance, anti-slip performance, and easy installation, widely used in industrial, construction, and infrastructure projects worldwide.

-

Precision Manufacturing Processes

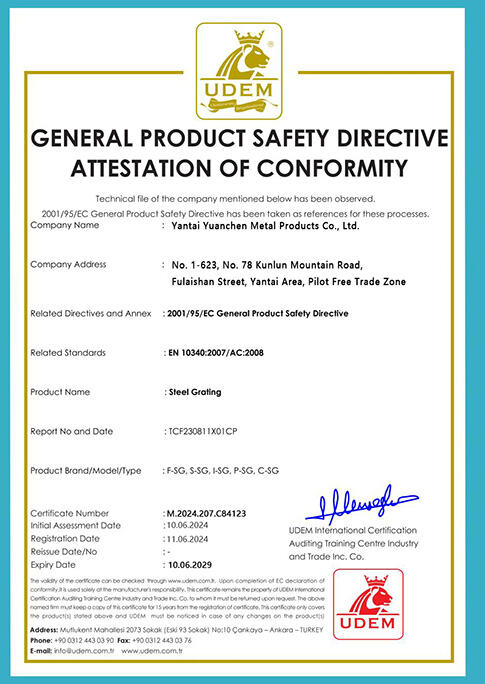

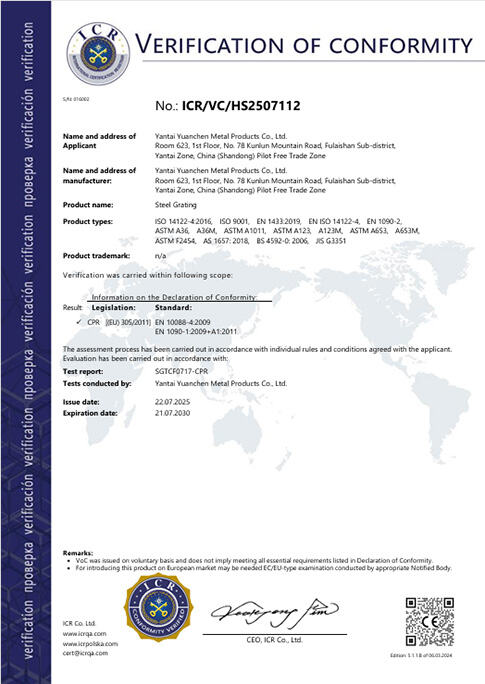

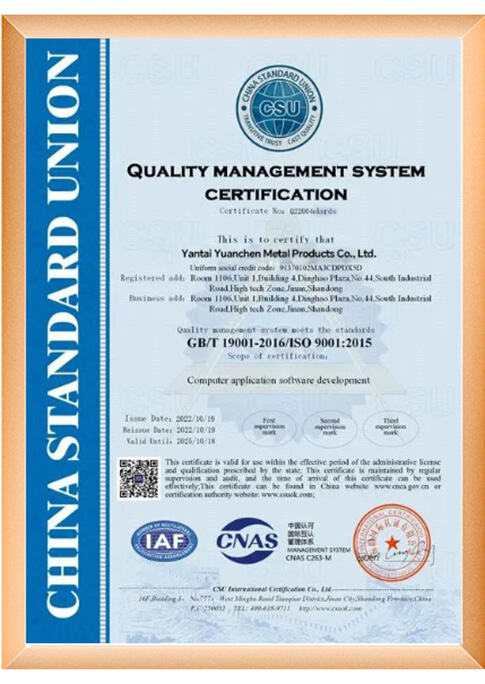

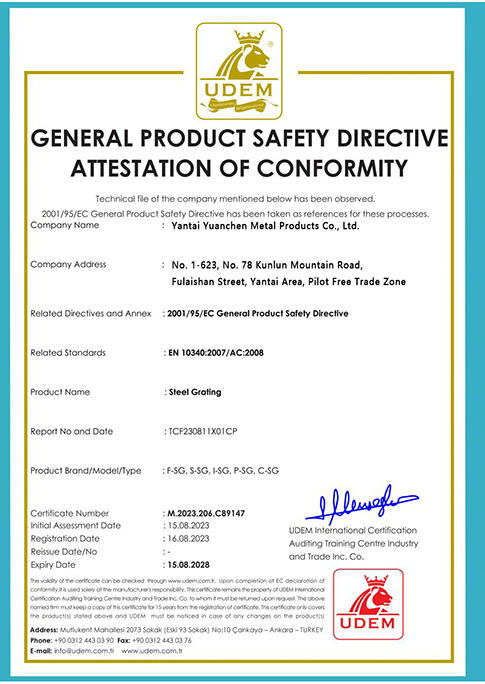

Compliant with ISO 9001, CE, SGS certifications

-

Rapid Delivery Capability

With our production facilities, we can efficiently respond to urgent orders, thereby shortening project cycles

-

Customized Solutions

We support non-standard size and material requirements, provide guidance and technical support to meet process conditions

Product description

Introduction to Special Steel Gratings for Offshore Platforms, Ports and Terminals

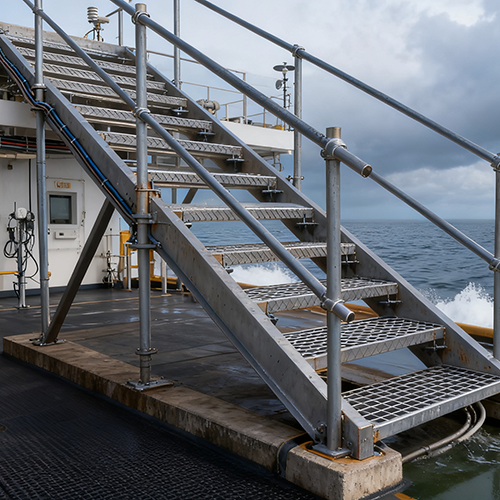

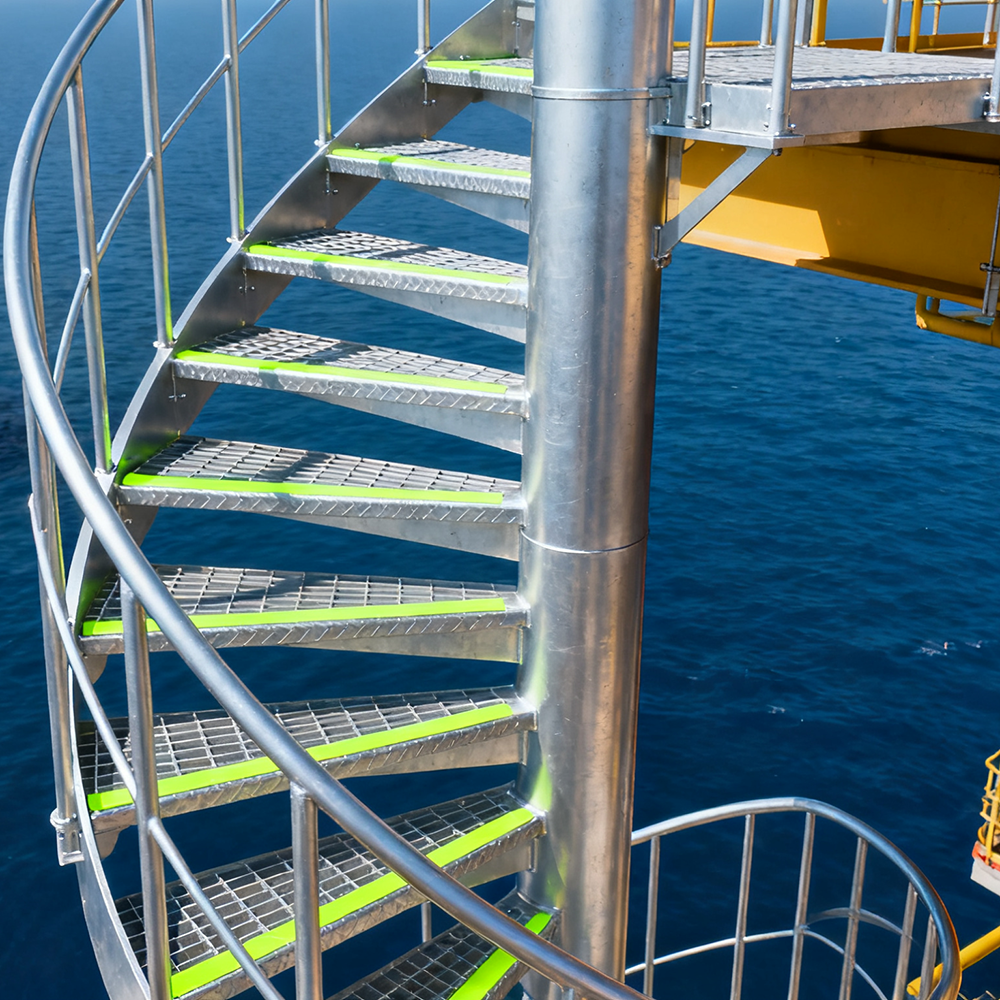

In the field of marine and port engineering, steel gratings, as key structural components, are widely used in core scenarios such as ship decks, port operation platforms, cross-sea bridge joints, and seawater desalination plants. They perform important functions including personnel passage, equipment bearing, and safety protection, serving as one of the infrastructure facilities ensuring the operation of marine engineering and ports.

The service environment in this industry is highly special and challenging. Steel gratings must be exposed to high-salt, high-humidity marine atmosphere for a long time, frequently suffer from salt spray erosion,and remain in a damp state all year round. These environmental threats not only accelerate the aging of steel gratings but also directly affect their structural stability and operational safety.

For marine and port scenarios, the core pain points of steel gratings focus on four aspects: first, salt spray corrosion—high-concentration salt is easy to penetrate ordinary protective layers, leading to steel rust and strength reduction; second, wet slipping—damp surfaces are prone to cause personnel slipping accidents, especially in platform areas with frequent movement of operators; third, marine organism attachment—attachment of marine algae, shellfish, etc., will increase the load of steel gratings and accelerate local corrosion; fourth, wind and wave impact—extreme weather such as typhoons and huge waves may cause physical damage to steel gratings, affecting the stability of the overall structure.

To adapt to the harsh environment of oceans and ports, steel gratings must be made of special steel materials with excellent salt corrosion resistance in terms of product material, These materials can resist salt erosion through their own chemical stability and extend service life; meanwhile, they need to have high mechanical strength to withstand long-term impact from ocean waves and equipment.

In terms of key processes, three technical guarantees are required for performance: first, the heavy galvanizing process is adopted to form a dense protective layer, blocking the contact between salt and steel; second, the anti-slip strip pressing process is used to form concave-convex textures on the surface of steel gratings, improving the friction coefficient in humid environments and reducing the risk of slipping; in addition, anti-attachment treatment (such as coating marine anti-biofouling paint) is needed to reduce the attachment of marine organisms and lower maintenance costs.

In summary, through targeted material selection and process design, special steel gratings for offshore platforms, ports, and terminals achieve the core functions of "salt corrosion resistance, anti-slip, impact resistance, and easy maintenance", providing safe and reliable structural support for marine engineering and port operations.

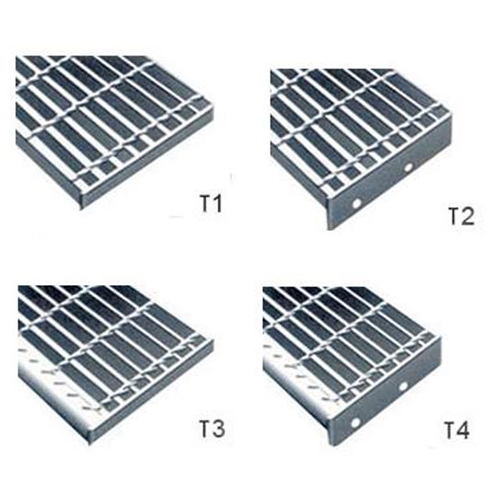

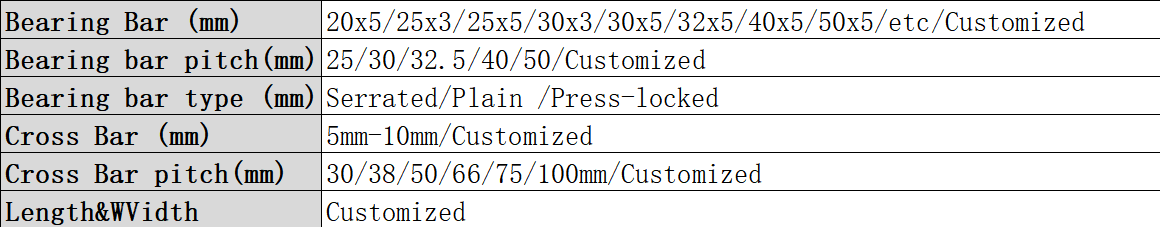

Parameter

Our Advantages

What are the advantages of Shandong Yuanchen's steel grating

Scene

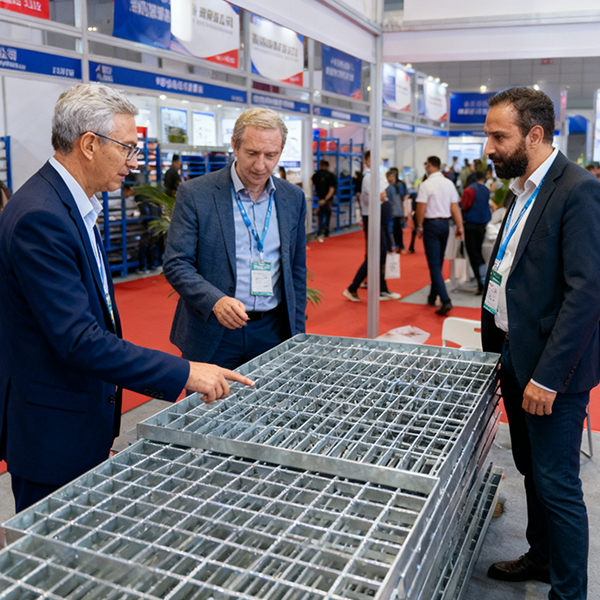

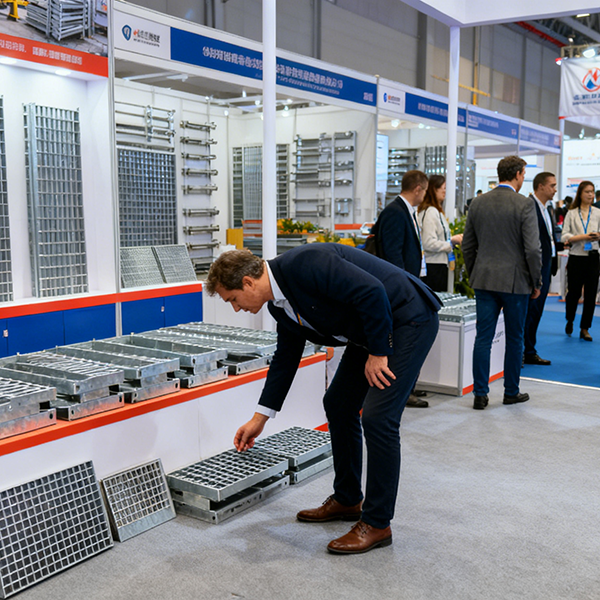

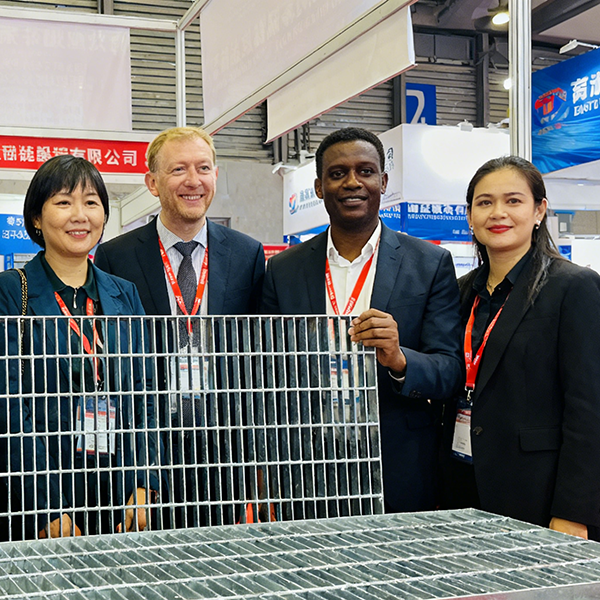

Exhibition

Delivery and Logistics

Certificate