Product description

Introduction to Steel Grating Stairs for the Petrochemical Industry

In petrochemical production environments, steel grating stairs serve as crucial metal components, widely applied in key locations such as chemical workshops, reactor peripheries, acid-alkali tank farms, and oil tank farms. They fulfill essential functions including platform flooring, walkway construction, and safety protection.

The operating environment of the petrochemical industry is highly challenging. Steel grating stairs must withstand multiple environmental hazards such as strong acids, alkalis, corrosive gases, and flammable/explosive media. These factors not only affect the service life of steel grating stairs but are also directly related to production safety.

The core pain points of steel grating stairs in this industry mainly focus on three aspects: first, corrosion and rust, which directly lead to reduced performance; second, spark generation that may trigger explosions—a significant safety hazard in flammable and explosive environments; third, structural strength degradation, which could cause safety accidents.

To meet these special requirements, steel grating stairs for the petrochemical industry must be made of high-strength, corrosion-resistant special steels such as galvanized high-strength steel. This ensures resistance to harsh environmental erosion and maintains structural stability.

Meanwhile, strict control must be exercised over key manufacturing processes: first, professional anti-corrosion coating treatment to enhance acid-alkali resistance and corrosion resistance; second, spark-proof design to avoid spark generation due to friction or collision during use; in addition, sealed welding technology is indispensable to ensure the tightness of the overall structure, preventing medium leakage and the infiltration of corrosive substances into the interior.

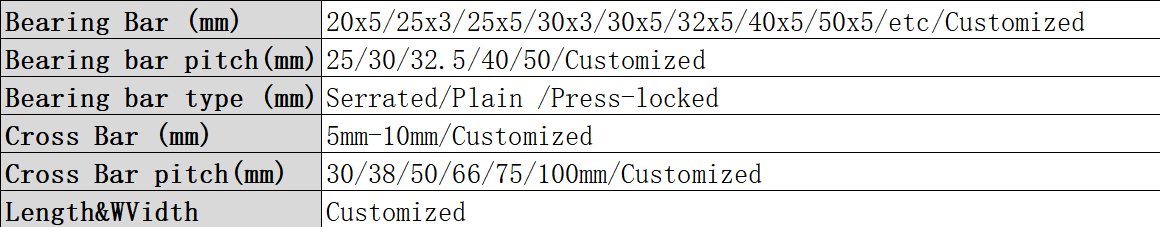

Parameter

Our Advantages

What are the advantages of Shandong Yuanchen's steel grating

-

Full Material Coverage

Our steel grating is manufactured with premium low-carbon steel or stainless steel, through advanced welding/riveting technology. It features high strength, corrosion resistance, anti-slip performance, and easy installation, widely used in industrial, construction, and infrastructure projects worldwide.

-

Precision Manufacturing Processes

Compliant with ISO 9001, CE, SGS certifications

-

Rapid Delivery Capability

With our production facilities, we can efficiently respond to urgent orders, thereby shortening project cycles

-

Customized Solutions

We support non-standard size and material requirements, provide guidance and technical support to meet process conditions

Scene

Exhibition

Delivery and Logistics

Certificate(证书

FAQ

Q1: Does it comply with international standards?

A1: All products comply with ISO 9001 quality management system certification and adhere to international standards such as ASTM, EN, and BS, ensuring that core indicators meet the required standards.

Q2: Can the steel grating be customized according to my drawings or size requirements?

A2: Support full-specification customization services! The size, grid spacing, thickness, and surface treatment can all be adjusted according to your drawings or needs.

Q3: What is the production lead time for an order?

A3: Sample needs 1-2 days, mass production usually within 10-25 days after determining the customer's requirements.

Q4: Is there a warranty provided? How to handle quality issues if they occur?

A4: We offer a 3-year warranty, excluding any damage caused by human factors. In case of any quality issues, please feel free to contact our customer service team.