Product description

Stair handrails (including supporting railings) are indispensable core safety protection components in various scenarios, widely used in diverse fields such as industrial production, municipal construction, energy facilities, and marine engineering. Forming an integrated protection system with steel grating stairs, operation platforms, and passages, they undertake key functions including fall prevention for personnel passage, emergency evacuation guidance, and environmental adaptation protection. Their design always takes "safety redundancy, durability and adaptability, and convenience and practicality" as the core, building a solid line of defense for passage and operational safety in different scenarios.

As basic safety facilities, the core design of stair handrails strictly complies with universal safety specifications: the height of handrails uniformly meets industry standards (≥900mm for conventional scenarios, ≥1100mm for high-altitude and hazardous areas), and the spacing between vertical railing bars is ≤110mm, effectively eliminating the risk of personnel and tools falling; the grip diameter of handrails is controlled at 32-38mm, with a smoothly polished surface (roughness Ra ≤6.3μm) and rounded edges (radius ≥5mm), ensuring a stable and comfortable grip while avoiding collisions and scratches. The structural strength adopts a redundant design: the connection between handrails and columns is reinforced with double bolts, with a horizontal thrust resistance of ≥2.0kN/m and a column spacing of ≤1500mm, which can withstand instant impact without loosening or deformation, ensuring stability during long-term use.

In terms of material and process selection, durability and scenario adaptability are balanced: the main materials are high-strength steel etc. According to the service environment, special processes such as hot-dip galvanizing, anti-corrosion coating, and insulation treatment can be matched, which can not only resist the impact of natural and industrial environments such as outdoor wind and rain, humid salt spray, and chemical erosion but also meet special functional requirements such as high temperature resistance, insulation, and anti-static; surface treatment supports diversified customization to adapt to the aesthetic and practical requirements of different scenarios. At the same time, a modular splicing structure is adopted, enabling convenient and efficient installation, greatly improving the construction progress and reducing maintenance costs.

In addition, the product fully complies with various universal safety standards and is equipped with complete certification documents such as material testing and strength testing, with a long service life and no dead ends in safety details—no welding burrs or sharp protrusions, and quick-release buckles are installed at emergency exits. It not only does not hinder emergency evacuation but also achieves the dual value of "safety protection + convenient operation and maintenance" in daily use, becoming a core protection component with both reliability and adaptability in infrastructure across various fields.

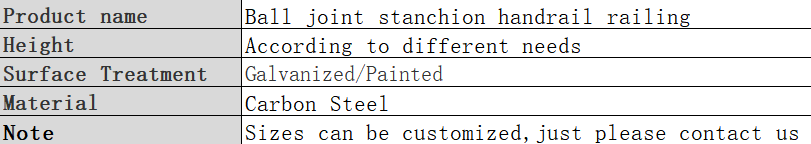

Parameter

Our Advantages

What are the advantages of Shandong Yuanchen's steel grating

-

Full Material Coverage

Our steel grating is manufactured with premium low-carbon steel or stainless steel, through advanced welding/riveting technology. It features high strength, corrosion resistance, anti-slip performance, and easy installation, widely used in industrial, construction, and infrastructure projects worldwide.

-

Precision Manufacturing Processes

Compliant with ISO 9001, CE, SGS certifications

-

Rapid Delivery Capability

With our production facilities, we can efficiently respond to urgent orders, thereby shortening project cycles

-

Customized Solutions

We support non-standard size and material requirements, provide guidance and technical support to meet process conditions

Scene

Exhibition

Delivery and Logistics

Certificate

FAQ

Q1: Does it comply with international standards?

A1: All products comply with ISO 9001 quality management system certification and adhere to international standards such as ASTM, EN, and BS, ensuring that core indicators meet the required standards.

Q2: Can the steel grating be customized according to my drawings or size requirements?

A2: Support full-specification customization services! The size, grid spacing, thickness, and surface treatment can all be adjusted according to your drawings or needs.

Q3: What is the production lead time for an order?

A3: Sample needs 1-2 days, mass production usually within 10-25 days after determining the customer's requirements.

Q4: Is there a warranty provided? How to handle quality issues if they occur?

A4: We offer a 3-year warranty, excluding any damage caused by human factors. In case of any quality issues, please feel free to contact our customer service team.