Steel Grating Unleashed: How Innovative Grid Designs Are Redefining Strength, Safety & Sustainability Across Industries

In an era where industrial and urban infrastructure demands increasingly smarter, safer, and more sustainable materials, one engineered product is quietly proving its mettle across the globe: modern steel grating. Far more than a simple metal mesh, today’s advanced steel Grating solutions represent a perfect synergy of intelligent design, material science, and manufacturing innovation. For B2B buyers, project specifiers, and procurement managers in sectors ranging from heavy industry to municipal development, understanding the full scope of steel grating’s evolution is key to making future-proof purchasing decisions. This article explores the latest structural, performance, and technological leaps in steel grating and how they are expanding applications while setting new benchmarks for durability, efficiency, and cost-effectiveness.

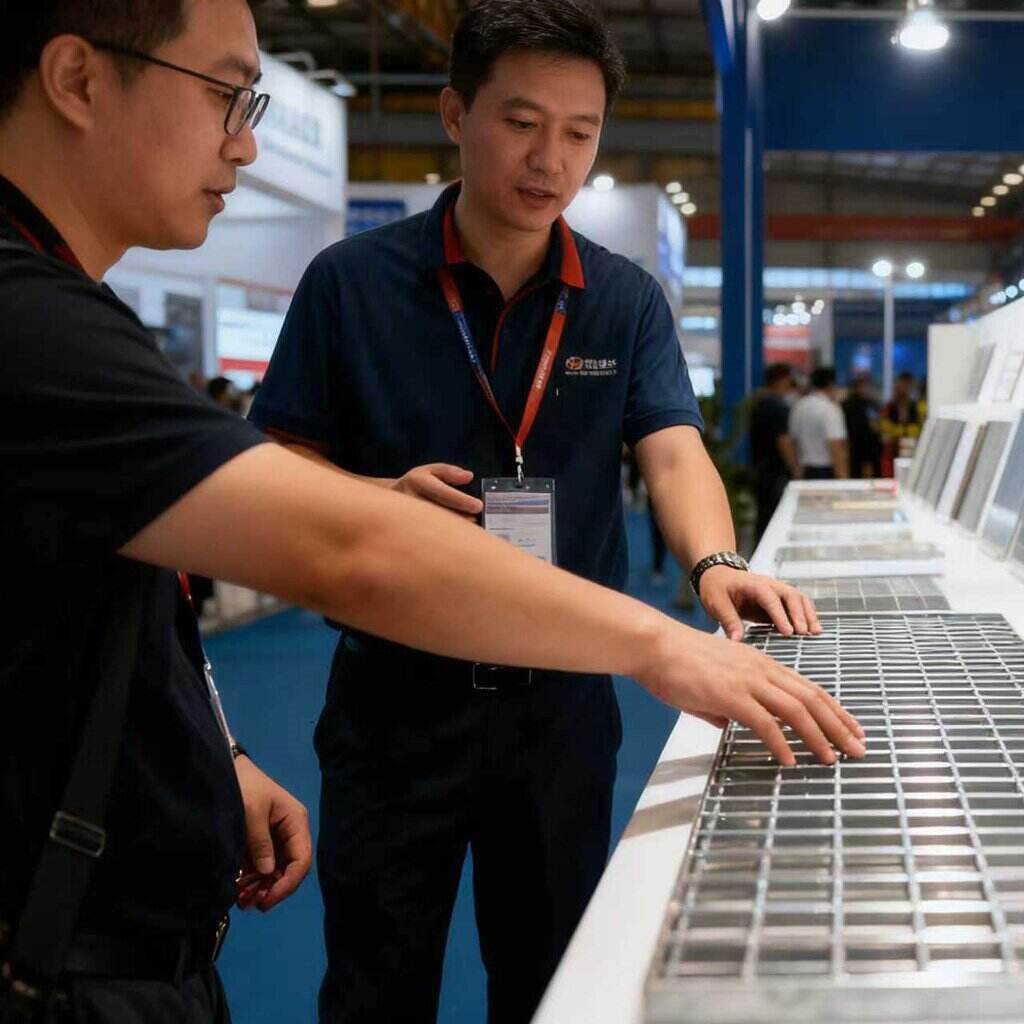

I: Structural Advantages – The Engineering Brilliance Behind the Grid

The fundamental strength of steel grating lies in its optimized grid-like architecture. Primary load-bearing bars carry the major loads, while uniformly spaced cross bars are integrally welded or locked into place, creating a rigid yet resilient tri-dimensional support system. This design achieves an exceptional strength-to-weight ratio – a critical advantage over solid plate alternatives like concrete or thick steel sheets.

How significant is the weight savings? Advanced steel grating can be over 60% lighter than concrete slabs of comparable load-bearing capacity. This dramatic reduction directly translates to lower logistics costs, easier on-site handling without heavy lifting equipment, and reduced structural load on supporting frameworks. For renovation projects or installations on existing structures, this lightweight property is a game-changer.

Furthermore, the modular nature of steel grating panels allows for rapid assembly and customization. They can be tailored and spliced to fit irregular layouts, complex terrains, or around obstructions, minimizing on-site cutting and waste. This adaptability accelerates project timelines and offers unparalleled design flexibility for platforms, walkways, and enclosures in industrial plants, energy facilities, and transportation hubs.

II: Performance Breakthroughs – Engineered for Extreme Duty & Daily Reliability

Modern steel grating isn’t just strong; it’s built to endure and perform in specific challenging environments.

Corrosion Resistance for Longevity: Through advanced surface treatment technologies like hot-dip galvanizing (the industry gold standard), powder coating, and polymer coating, steel grating forms a robust protective shield. The hot-dip galvanizing process creates a metallurgical bond with the steel, forming a zinc-iron alloy layer that offers sacrificial protection. This can grant a maintenance-free service life of 30 years or more, even in harsh coastal, chemical, or high-humidity settings, drastically reducing lifecycle costs.

Safety Through Superior Traction: Worker safety is paramount. The open grid pattern provides natural drainage and inherent slip resistance. For high-risk areas with oil, water, or chemical spills, manufacturers offer serrated surface bars or grip-strut patterns that dramatically increase the coefficient of friction, meeting and exceeding international safety standards (like OSHA, ISO) for slip resistance.

Ventilation, Light Transmission & Sustainability: The open area of grating allows free passage of air, light, and liquids. This ventilation prevents the accumulation of hazardous gases, reduces heat buildup around equipment, and mitigates moisture-related corrosion. The light transmission reduces the need for artificial lighting in areas like mezzanines, parking garages, or water treatment plants, contributing to energy savings. This aligns perfectly with green building principles by promoting energy efficiency and material efficiency.

III: Application Expansion – From Core Industrial to Smart Urban Infrastructure

The versatility of steel grating fuels its cross-industry adoption:

Industrial & Energy Backbone: It remains the go-to material for industrial flooring: plant platforms, catwalks, stair treads, and mezzanines in factories, refineries, and mills. In power generation and offshore oil & gas, specialized grating is used for cable trays, equipment galleries, and offshore platform decks, where its strength, corrosion resistance, and non-slip properties are critical.

Urban Infrastructure & Municipal Works: Cities are integrating steel grating into their fabric through trench drains, tree grates, pedestrian bridges, and sustainable drainage systems (SuDS). Its high load-bearing capacity handles vehicle traffic, while its permeability aids in stormwater management. Lightweight yet secure manhole and utility covers simplify access for maintenance crews.

Waste & Water Treatment: In environmental engineering, grating is essential as filter screens, walkways over settling tanks, and sludge handling platforms in wastewater and garbage treatment plants. Its open area allows fluid flow while supporting equipment and personnel.

Architectural & Aesthetic Integration: Beyond pure function, architects are leveraging steel grating for facade cladding, sunscreens, balcony balustrades, and interior features. Available in various finishes and patterns, it adds a contemporary, industrial-chic aesthetic while providing shade, security, and ventilation.

IV: The Technological Evolution – Smart Manufacturing & Future Trends

The steel grating industry is embracing Industry 4.0 and advanced materials:

Precision Manufacturing: Automated robotic welding ensures consistent, high-strength joints and perfect bar spacing. CNC laser and plasma cutting enable precise, complex shapes for custom fits and architectural designs, reducing material waste.

Smart Grating & IoT Integration: A frontier innovation involves embedding sensor modules within grating panels. These can monitor real-time load stress, structural fatigue, or environmental conditions, providing data for predictive maintenance and safety alerts in smart factories or critical infrastructure.

Material Science Advances: Research into composite and hybrid materials, such as grating incorporating fiberglass reinforcements or stainless steel alloys, pushes the boundaries of specific strength and chemical resistance for niche ultra-demanding applications.

Conclusion – The Strategic Material for a Demanding Future

From supporting massive industrial complexes to shaping resilient and efficient cities, steel grating has evolved from a simple component to a high-performance, multi-functional building block. Its ongoing innovations in design, durability, safety, and sustainability make it a strategically sound choice for B2B buyers worldwide.

As global infrastructure trends emphasize safety regulations, lifecycle cost savings, and environmental responsibility, the demand for intelligent, high-performance steel grating solutions is poised for significant growth. For businesses seeking reliable, long-term partners in this space, focusing on suppliers who invest in advanced manufacturing, quality certifications, and technical support is crucial.

Are you evaluating steel grating for an upcoming industrial, commercial, or municipal project?

Contact our expert team today to discuss your specific load, corrosion, and safety requirements. We provide customized solutions, technical data sheets, and global logistics support to ensure your project’s success with the right grating technology.